In mission-critical applications like security surveillance and industrial inspection, precision pan tilt heads rely on robust communication protocols. The RS485/RS422 + Pelco P/D combination remains the gold standard for global manufacturers. As a leading pan tilt head producer, we decode this core technology's competitive edge.

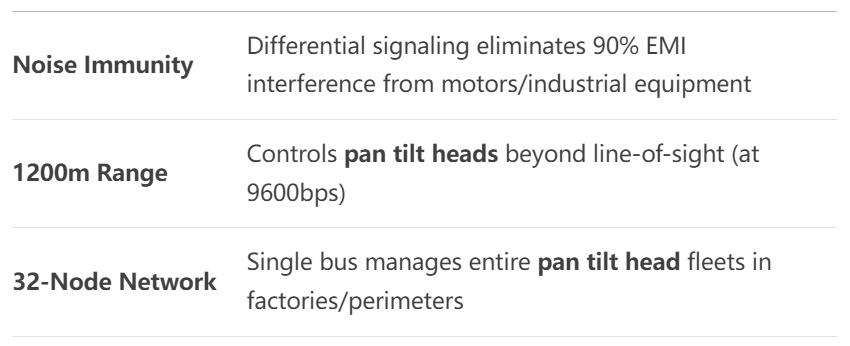

When standard interfaces fail in harsh environments, RS485/RS422 delivers three unbeatable advantages:

Feature | Impact on Pan Tilt Heads |

Industry Fact: 92% of industrial pan tilt positioners use RS485 for centralized control cost reduction.

Pelco D Protocol: The Language of Pan Tilt Control

As the de facto standard for pan tilt heads, Pelco D's 7-byte structure enables lightning-fast commands:

Command Frame for Pan Left (HEX)

FF 01 01 00 20 00 22

· FF: Sync byte

· 01: Pan tilt head address #1

· 01: Pan left command

· 20: Medium pan speed

· 22: Checksum validation

Key Protocol Advantages for Pan Tilt Heads:

✅ 3ms response time (vs. 15ms in Pelco P)

✅ 256 preset positions with recall function

✅ Native compatibility with 90%+ DVRs/NVRs

3 Business Benefits for System Integrators

Deploying RS485 + Pelco D pan tilt heads unlocks:

1. Zero-Failure Operations

Survives voltage spikes (±15kV ESD protection) in power plants/refineries

2. 40% Lower Installation Costs

Single cable runs vs. point-to-point wiring for multiple pan tilt units

3. Future-Proof Upgrades

New pan tilt heads integrate seamlessly with legacy Pelco D systems

As a security-focused pan tilt head manufacturer, we recommend verifying:

1. Protocol Compliance

Full Pelco D/P support without proprietary "enhancements"

2. Military-Grade Connectors

IP68-rated M12 ports (salt-spray tested)

3. Dynamic Voltage Handling

DC12-36V input range for unstable grids

4. Real-Time Diagnostics

Dual LED indicators for power/communication status

5. ±0.1° Positioning Accuracy

Gear train quality for critical surveillance

Our ISO-certified pan tilt heads deliver:

· Pelco D/P auto-detection

· 360° continuous pan + 120° tilt range

· 25kg payload capacity

Ziwin CCTV Cameras have a high quality. If you are interested in our products, please leave a message here, we will respond as soon as possible.