Supply chain security plays a crucial role in ensuring the safe transportation and storage of goods, especially in industries dealing with perishable items such as food, pharmaceuticals, and chemicals. In refrigerated logistics, maintaining the integrity of products is essential, which is why cold storage cameras have become a vital part of the monitoring infrastructure. These cameras are specifically designed to operate effectively in extremely low-temperature environments, helping to safeguard goods and enhance visibility within cold storage facilities. This article will explore how cold storage cameras contribute to improving supply chain security in refrigerated logistics.

Cold storage cameras are tailored to monitor and protect valuable goods in environments where temperatures often drop well below freezing. These cameras, designed to withstand extreme cold, ensure that inventory is monitored around the clock without compromising image quality or performance. For businesses in the food and pharmaceutical sectors, where temperature control is critical, cold storage cameras provide real-time surveillance to ensure that stored products remain within the required temperature ranges. The ability to monitor such environments remotely helps reduce the risks associated with human error and potential breaches in storage protocols. Furthermore, cold storage cameras often include advanced features such as motion detection, alarm notifications, and high-definition resolution, allowing operators to detect any irregularities quickly and take immediate action to prevent spoilage or damage to goods.

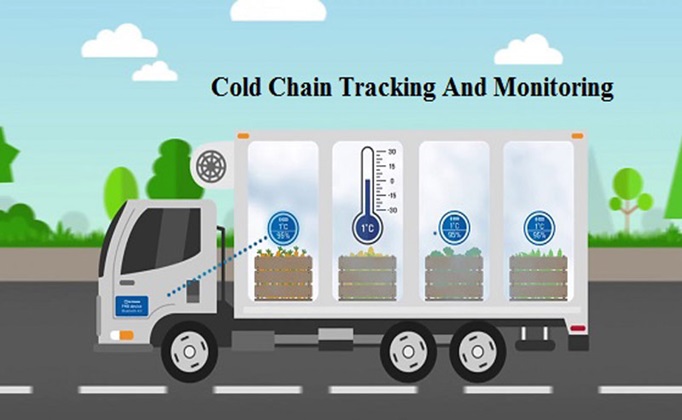

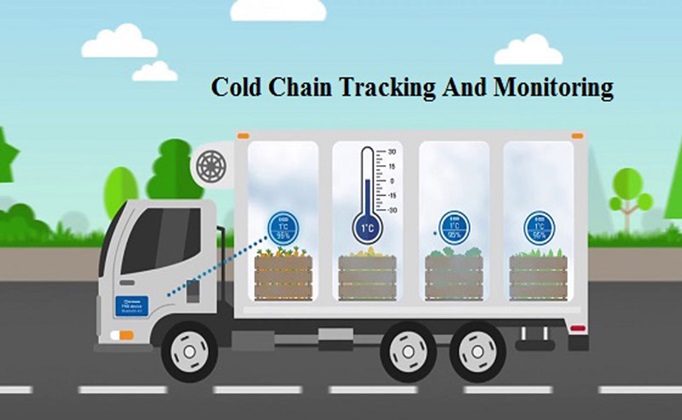

For companies that deal with perishable items, compliance with strict temperature regulations is a top priority. Cold storage cameras are integral to ensuring that temperature-sensitive products, such as vaccines, fresh produce, and frozen foods, are kept at optimal temperatures throughout the supply chain. These cameras not only allow for real-time monitoring of temperature conditions but also provide a visual record of any discrepancies. If a temperature breach occurs, the camera footage serves as vital evidence, helping businesses take corrective action promptly. Furthermore, when paired with temperature monitoring systems, cold storage cameras provide a comprehensive solution that can monitor both the physical environment and the security of the facility simultaneously. This combination reduces the likelihood of spoilage, ensures product integrity, and helps companies meet regulatory compliance standards effectively.

In addition to temperature monitoring, cold storage cameras play a crucial role in deterring theft and preventing tampering with inventory. Refrigerated warehouses and distribution centers often store high-value goods, making them potential targets for theft. The presence of cold storage cameras in and around storage areas provides a deterrent effect, as potential intruders are less likely to attempt to steal or tamper with goods if they know they are being monitored. Furthermore, these cameras provide a clear record of any suspicious activity, enabling businesses to investigate incidents and identify culprits. In the event of a security breach, the footage captured by cold storage cameras can be used to aid in legal proceedings or insurance claims, providing valuable evidence of wrongdoing and strengthening overall security protocols.

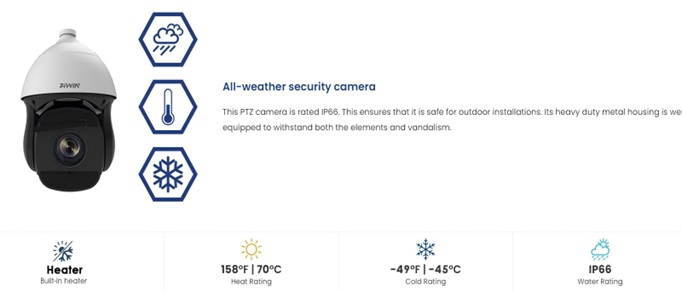

While traditional CCTV systems may suffice in many standard environments, they are not always well-suited to the extreme conditions found in cold storage facilities. Cold storage cameras are specifically designed to operate effectively in freezing temperatures without the risk of malfunction or reduced performance. Standard surveillance systems, which are not built for subzero environments, may experience failure due to condensation, freezing, or difficulty maintaining image clarity in low-light conditions. Below is a comparison between cold storage cameras and standard surveillance cameras:

Feature | Cold Storage Camera | Standard Surveillance Camera |

Temperature Resistance | Designed for extremely cold environments | May fail or degrade in freezing temperatures |

Durability | Built with materials that withstand subzero conditions | Not designed for harsh conditions |

Image Clarity in Low Light Conditions | High, with IR and low-light capabilities | May suffer from blurry or grainy images in low light |

Motion Detection | Enhanced detection even in dark, cold spaces | May not perform well in low visibility conditions |

As illustrated, cold storage cameras are specifically designed to endure and perform optimally in cold environments, ensuring that the footage remains clear and reliable in conditions where standard systems might fail.

In conclusion, cold storage cameras are an essential component for ensuring security and compliance in refrigerated logistics. They provide real-time monitoring of both temperature and security conditions, offering a solution that helps prevent spoilage, theft, and tampering. By integrating cold storage cameras into the monitoring infrastructure, businesses can safeguard their valuable inventory, ensure regulatory compliance, and enhance overall operational efficiency. These cameras offer unique advantages over standard surveillance systems, particularly in cold storage environments, making them indispensable for industries that rely on strict temperature control.

References

Ziwin CCTV Cameras have a high quality. If you are interested in our products, please leave a message here, we will respond as soon as possible.