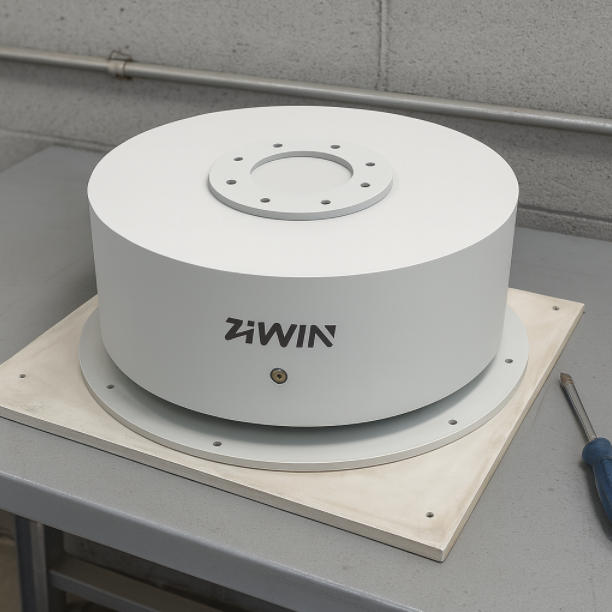

A single axis positioner is widely used in antenna systems, radar scanning, robotics platforms, industrial inspection, and surveillance. With proper maintenance, it can deliver long-term stability, precise rotation, and reliable performance in both indoor and outdoor environments. Although the structure is simpler than a traditional pan tilt unit, scheduled maintenance is still essential to ensure optimal operation and extended service life.

Routine inspections help identify early issues before they affect system performance. Monthly or quarterly checks are recommended depending on usage and environment.

Check the housing for cracks, corrosion, or deformation

Confirm that connectors remain sealed

Tighten any loose mounting screws

Inspect cables for wear, bending, or compression

Check for moisture, condensation, or water ingress, especially outdoors

Rotate the single axis positioner to verify smooth motion

Ensure there are no sudden jerks or excessive backlash

Listen for unusual noise or vibration

Confirm angle feedback and presets function correctly

Inspect for dust, sand, salt fog, or extreme temperature effects

Ensure that external protective housings remain intact for outdoor use

Regular maintenance helps preserve rotational stability and system accuracy over long-term use.

Lubricate bearings and mechanical joints as required

Refresh or replace gearbox grease if the design includes one

Recommended interval: 12–18 months for outdoor use; longer for indoor applications

Inspect sealing components such as O-rings and gaskets

Remove accumulated dust or debris

Reinforce waterproofing as needed after environmental exposure

Confirm payload remains firmly mounted

Ensure that the center of gravity has not shifted

Check for wobbling or imbalance during rotation

Annual or long-term maintenance focuses on restoring mechanical precision and evaluating worn components.

Bearings

Gearbox seals

O-rings

Lubricants

Slip-ring brushes (for continuous rotation models)

Calibrate angle sensors

Verify zero and limit positions

Check rotation accuracy and consistency

Confirm torque output under load

Test for overheating or abnormal noise

Measure current draw for abnormalities

Evaluate acceleration and braking performance

Confirm control electronics are stable and responsive

Below are common symptoms and recommended diagnostic steps.

Possible causes:

Insufficient lubrication

Bearing fatigue

Dust or debris inside gearbox

Unstable base or mounting issues

High payload center of gravity

Possible causes:

Sensor drift or contamination

Encoder dust accumulation

Mechanical backlash increase

Electrical signal interference

Possible causes:

Overload or excessive torque demand

Unstable supply voltage

Motor wear or aging

High ambient temperature

Possible causes:

Worn slip-ring contacts

Moisture inside slip-ring cavity

Fatigue of internal wiring

Excessive rotation speed

Compared with a pan tilt unit, a single axis positioner typically has:

A simpler mechanical structure

Only one rotating axis and one motor

Fewer sealing points for waterproofing

Lower risk of mechanical misalignment

Less complex calibration

Reduced annual maintenance cost

These advantages make it highly suitable for applications requiring only pan rotation or tilt rotation, such as a pan rotate positioner or tilt rotate positioner, without the complexity of a dual-axis system.

Do not exceed the rated load

Keep the center of gravity as low as possible

Use protective covers in harsh outdoor environments

Avoid extended periods of maximum-speed rotation

Perform lubrication and sealing checks regularly

Use surge protection for motor drivers

Avoid rapid, frequent, large-angle direction changes

A single axis positioner can deliver long, stable, and precise performance when supported by proper maintenance. Its simple structure makes it easier to service than a typical pan tilt unit, and routine lubrication, sealing checks, calibration, and load inspections can greatly extend its operational lifespan.

Whether used as a pan rotate positioner or tilt rotate positioner, it offers reliable and low-maintenance motion control ideal for industrial, robotic, antenna, and surveillance applications.

Ziwin CCTV Cameras have a high quality. If you are interested in our products, please leave a message here, we will respond as soon as possible.