In the field of security surveillance, the drive method of a PTZ mount directly impacts device performance and lifespan. As an Technical team with 18 years of R&D experience, ZIWIN will analyze the core differences between gear drive and belt drive systems from technical principles, application scenarios, and maintenance cost perspectives.

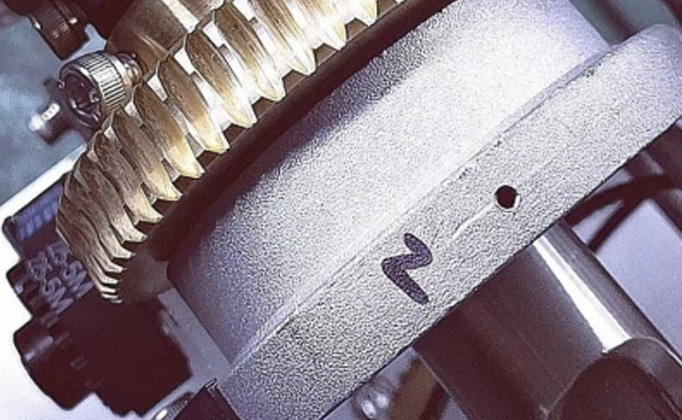

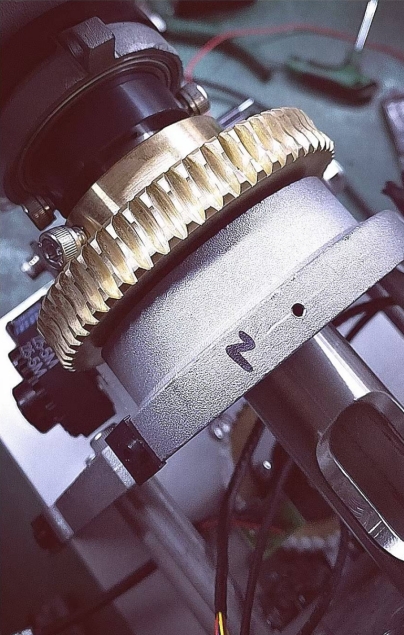

1. Gear Drive System

Structural Features:

· Uses helical/planetary gear sets

· Metal gears engage directly

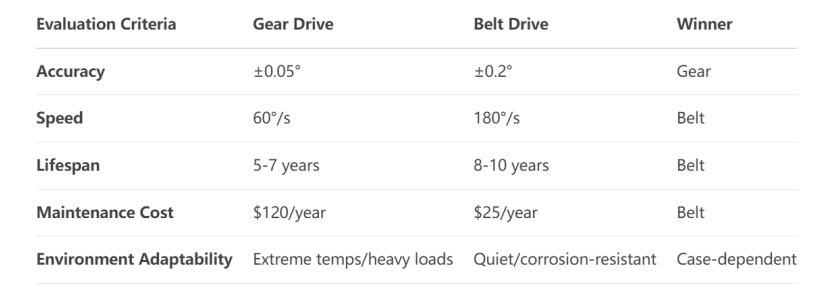

· Equipped with high-precision encoders (±0.05°)

Advantages:

✔ Ultra-high torque output (supports up to 50kg loads)

✔ High positioning accuracy (repeatability error <0.1°)

✔ Extreme temperature resistance (-40℃~85℃ range)

Disadvantages:

✖ Higher operational noise (50-65dB)

✖ Requires regular lubrication maintenance

2. Belt Drive System

Structural Innovations:

· Carbon fiber-reinforced timing belts

· Auto-tensioning mechanism

· Non-contact encoders

Advantages:

✔ Ultra-quiet operation (<35dB)

✔ Maintenance-free design (no lubrication needed)

✔ High-speed response (180°/s instant movement)

Disadvantages:

✖ Lower load capacity (typically <15kg)

✖ Potential belt stretch over time

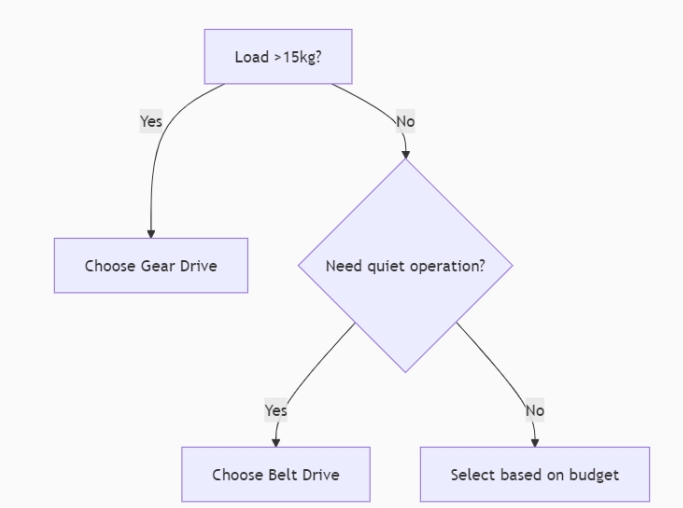

Decision Flowchart:

Ideal for Gear Drive:

1. Heavy-duty monitoring: Port crane surveillance, power substation inspection

2. High-precision needs: License plate recognition, border patrol

3. Extreme environments: Middle Eastern deserts, Arctic research stations

Ideal for Belt Drive:

1. Noise-sensitive areas: Museums, hospital operating rooms

2. High-speed tracking: Traffic violation capture, anti-drone systems

3. Corrosive environments: Coastal regions, chemical plants

Q1: How to identify existing PTZ drive type?

3-Step Identification:

1. Listen: Gear drives produce rhythmic "clicking" sounds

2. Check model: "G"/"Gear" indicates gear drive; "B"/"Belt" for belt drive

3. Review manual: Drive type specified in technical parameters

Q2: Will belt drives fail in low temperatures?

· Standard belts: May become brittle below -10℃

· Specialty belts: Polyurethane material (operates at -40℃)

· Solution: Choose PTZ with temperature control

Q3: Do gear drives require regular oiling?

· Traditional models: Lubricate every 2 years

· New models: Solid lubricant coating (5-year maintenance-free)

· Tip: Use Molykote EM-series specialized grease

1. Smart Hybrid Drive:

o Belt drive at low speed (quiet/energy-saving)

o Gear engagement at high speed/heavy load (ensures precision)

2. Self-Diagnostic Systems:

o Real-time gear wear monitoring

o Predictive belt lifespan analysis

o Maintenance alerts via app

3. Advanced Materials:

o Graphene-enhanced gears (40% less wear)

o Bio-based biodegradable belts (eco-friendly solution)

Gear Drive:

· Lubricant replacement every 2 years ($50/instance)

· Gear set replacement every 5 years ($200)

Belt Drive:

· Timing belt replacement every 5 years ($80)

· No other maintenance required

Annualized Cost:

· Gear drive: $70/year

· Belt drive: $16/year

1. Critical infrastructure: Choose gear drive for reliability

2. Commercial venues: Belt drive offers better cost efficiency

3. Special requirements: Consider customized hybrid solutions

For specific product selection advice, contact our technical team for the PTZ Drive System Selection Guide (includes detailed parameter comparisons).

Ziwin CCTV Cameras have a high quality. If you are interested in our products, please leave a message here, we will respond as soon as possible.